Project Details

Mazdat Ltd Kano NG

Kano Municipal

2021

Manufacturing Industry

Project Overview

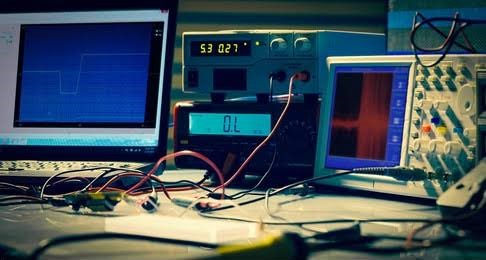

Calibration of process instruments is a critical process in ensuring accuracy and reliability in industrial settings. It involves comparing the measurements of an instrument against a known standard to determine any deviations and adjusting the instrument accordingly.It ensures that instruments provide accurate and reliable measurements, which are essential for maintaining quality, safety, and efficiency in various industrial processes.

Calibration Standards: Calibration is performed against established standards such as national or international standards, manufacturer specifications, or internal company standards. These standards provide reference points for accuracy and reliability.

Frequency: Calibration frequency is determined based on factors such as the instrument’s criticality, usage environment, regulatory requirements, and manufacturer recommendations. Some instruments may require calibration daily, while others may be calibrated annually or less frequently.

Traceability: It’s crucial to maintain traceability during calibration, ensuring that measurements can be traced back to national or international standards. This ensures the reliability and validity of calibration results.

Qualified Personnel: Calibration should be performed by trained and competent personnel following standardized procedures. They should have the necessary skills and knowledge to perform accurate calibrations and interpret results effectively.

Equipment and Facilities: Adequate equipment and facilities are required to perform calibration effectively. This includes calibrated reference standards, controlled environmental conditions, and proper maintenance of calibration equipment.